Helpful Engineering UK

Helpful Engineering is a global volunteer organisation of over 3,400 people including engineers, medics and scientists that have come together to support the world in coping with the crisis of COVID-19. Currently it focuses on providing face shields for key workers, but it is continuously looking to develop, and problem solve.

Helpful Engineering UK has recently launched a Hackney Hub, pulling together local people from various backgrounds to coordinate, produce and deliver face shields. This is an entirely volunteer programme that can be best described as a spider web - a vast network of people working from their homes and workshops constantly in contact, responding and resourcing the frontline communities in this pandemic.

Helpful Engineering UK has recently launched a Hackney Hub, pulling together local people from various backgrounds to coordinate, produce and deliver face shields. This is an entirely volunteer programme that can be best described as a spider web - a vast network of people working from their homes and workshops constantly in contact, responding and resourcing the frontline communities in this pandemic.

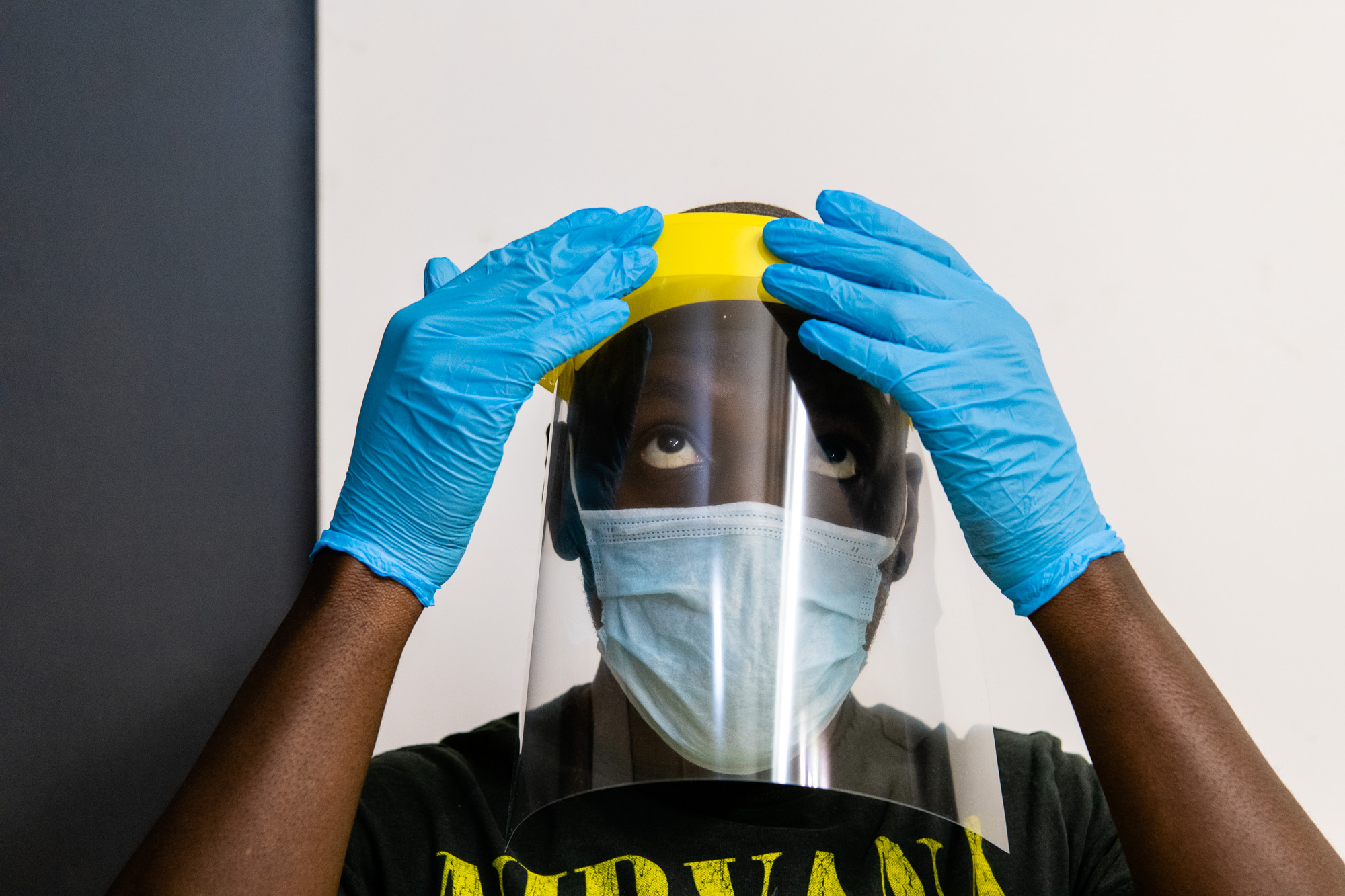

There are two shields that are being produced, soft shields which are made by laser cutting and hard shields which are printed on 3D printers. The laser cut shields are quickest to be produced, with approximately 22 an hour being created, whereas the 3D printers can make max 40 a day, and that’s only if you can work out a few hacks to the system! The original designs came from Ken Chew in Hong Kong, who shared them to the Helpful Engineering network. The network is built on shared knowledge, it is a collaborative, open source styled community.

The heart of the hub is to be hyper local, to serve and be served by, the those in close proximity. This allows for people to work from their homes, and for delivery people to not be travelling far, therefore everyone can work in safe environments.

One of the producers is Building Bloqs, in Enfield. They are an open-access workshop that has opened during this time specifically for individuals in its 400 strong members to work on producing the soft shields. Nick Newman, the Director of U-Build, a non-profit company that makes flat pack buildings in Hackney, has been one of the key people working at Building Bloqs for this purpose. There are two shifts a day - 7am until late at night - and for safety reasons two people are on site at once monitoring the large laser machines (but as it is a big workshop space they are able to operate within a safe environment), with a huge roster of volunteers. This week they had the 5000th shield collected, and they can make up to 500 shelfs a day.

Iva Stanisheva, an architect, runs the Hackney Hub from her flat; she came on board helping to deliver shields, then worked a few shifts at Building Bloqs a workshop space that can laser cut the soft shields, and now as coordinator for the North East Distribution Hub.

Iva’s flatmate Josh Haywood is also an architect, working for WATG who kindly lent him two 3D printers so that he is able to set up a production line in one of their rooms. This is a typical set up across the various homes and workspaces, where individuals are setting up personal ‘workshops’ to fill the requests from various frontline workers.

The requests for shields often come through from individuals, such as team leaders within medical teams, care homes and other frontline jobs, who are looking to protect themselves and their teams. They fill in a request form on the Helpful Engineering UK site, which then gets directed to the appropriate location Hubb, who organises production and deliver.

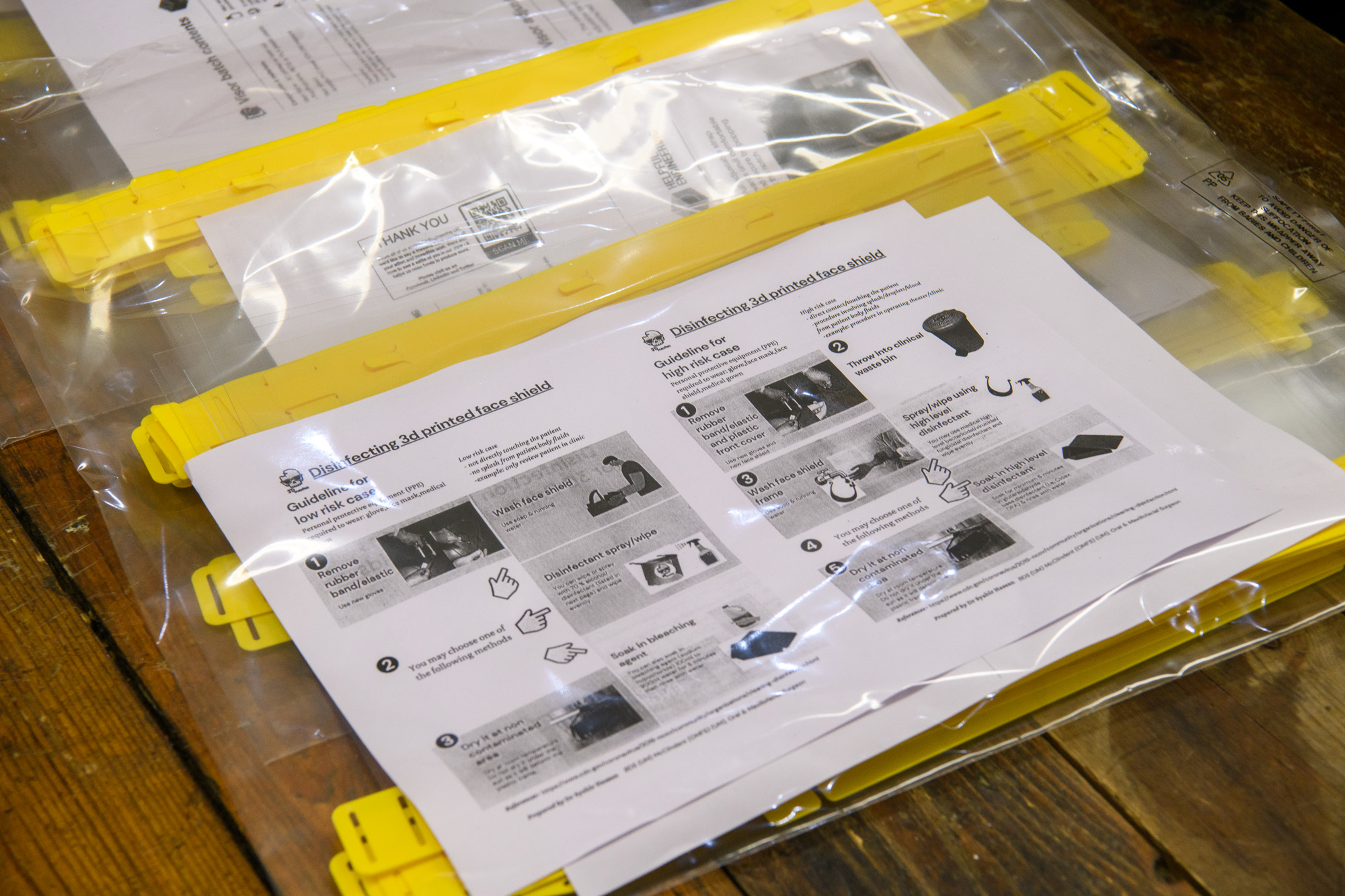

“There are a lot of WhatsApp groups and constant conversation” Iva explained, the essential part to this operation is organisation and communication. “We have set up very clear instructions and processes on the website so that everyone, at any point in the chain – from delivery, producers to recipients – knows exactly what is needed from them, and what to expect”.

This organisation has only been active for the global crisis, and the UK branch has been operating for one month. It is astonishing how much need there is for this service, and the effort from so many people. Shing Mon Chung, who is from a marketing background and is volunteering with the project around communications, explained “in the group’s first month, 15,000 visors have been produced and distributed to frontline workers in 22 London hospitals, 28 care homes, 34 COVID hot clinics and GP surgeries. The initiative now has 200 members, all volunteers, who produce, assemble and deliver visors.”

It is important to note that these shields are not PPE certified equipment but are still in great need and do form a key function in protecting people. They are designed to be reusable and cost 60p to make; the project is funded by charitable donations, through their fundraiser.

It’s a project that shows how the hyper-local is part of a global community, how a flat in Hackney has an effect on a wider world. It is about the ever connected-ness of a small communities; through communication, connections and action a lot can happen.

DONATE TO HELPFUL ENGINEERING CROWDFUNDING PAGE HERE